Lightweighting

Applying simulation upfront in the product development process means you can meet your performance targets by designing lightweight earlier instead of working to take mass out later. We develop and implement intelligent simulation technologies that allow you to find the optimal balance between weight, performance, and cost for your products. Altair accelerates your lightweighting initiatives with topology optimization, advanced materials, and pioneering innovation.

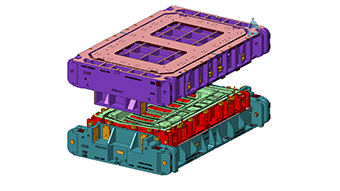

Design Plastic Parts

When a manufacturer needs to combine design freedom with lightweighting and cost requirements for complex parts, injection molding is in the focus. Develop innovative plastic parts quickly with Altair's comprehensive set of engineering plastic solutions

Design Composite Structures

When extreme lightweight requirements meet ultimate performance needs, continuous fiber reinforced materials are the solution of choice. Tailor products to meet individual requirements with a holistic simulation of continuous fiber composites

Design for Additive Manufacturing

Our simulation-driven design approach utilizes topology optimization while assuring part manufacturability, which is key to unlock the advantages of additive manufacturing Focusing on structural performances from the beginning leads to the most efficient, lightweight product design.

How can we help you to make your product lighter?

Contact UsTopology Optimization

Topology optimization develops optimized structures by considering design parameters like expected loads, available design space, material, and cost. Embedded early, it enables the creation of designs with minimal mass and maximal stiffness. For more than two decades, Altair® OptiStruct® is the original topology optimization structural design tool and has driven the design of products you see and use every day.

- Right the First Time: Create optimal designs early and reduce costs associated with design failure.

- Exceed Performance Targets: Maximize performance by starting with part and assembly designs that withstand all real-world conditions and loads.

- Design for Manufacturability: Find the best material distribution for your traditional or advanced manufacturing process and compare designs.

Altair® Inspire™brings OptiStruct into a new user experience encouraging earlier application of topology optimization. Both tools consider multiple manufacturing constraints, including symmetry patterns, draw direction, cavity avoidance, overhand angles, and extrusion. Topology optimization allows for fast design exploration, improved development productivity, and identifies opportunities for part consolidation.

Pioneering Innovation

The Altair product engineering services team works across industries in order to use processes and techniques from one industry and apply them to another. We've taken composite design techniques from the aerospace industry and applied them to passenger cars, and optimization processes from automotive and applied them to consumer goods. Our team creates industry-leading optimization solutions with our product development consultants to deliver the best possible technology application that other companies cannot match.

The team uses the latest optimization techniques and processes to deliver innovative solutions for our clients' product weight, performance, and cost challenges. In the traditional design process, simulation technology is used as a verification tool, and results can be delivered too late to impact the design direction. We believe in a different approach - CAD and CAE are deployed in parallel.

The concept phase of product development often fails to deliver mature engineering data to support the program business case, often resulting in costs to correct issues. Altair's process is used to rapidly interrogate design alternatives in the early development stage to help eliminate the risk of using immature concept deliverables and potential downstream issues in product development.

Automotive’s Only Award Dedicated to Vehicle Lightweighting and Sustainability

We have a deep commitment to vehicle efficiency, so much so that we have established the automotive industry’s only award dedicated to vehicle sustainability and lightweighting. The Altair Enlighten Award honors the greatest sustainability and lightweighting advancements that show a successful commitment in reducing the carbon footprint, mitigating water and energy consumption, as well as successful efforts in material reuse and recycling. Sparking interest from industry, engineering, policymakers, educators, students, and the public alike, this annual award provides an environment to share the latest technology innovations dedicated to sustainability and lightweighting.

Featured Resources

Towards Efficient Composite Pressure Vessel Design

Competing future vehicle concepts have drives using clean energy stored in batteries or hydrogen. On-board storage of high-pressure hydrogen gas to supply fuel cells needs weight-efficient pressure vessels utilizing composite materials, that operate safely and reliably under challenging thermo-mechanical service conditions, be affordable and meet standards. Partnering with the Altair Composites Team, CIKONI identified the benefits of Altair Multiscale Designer™ to increase simulation efficiency by its virtual material characterization to create accurate and reliable material models for structural simulation. They applied Multiscale Designer, Altair OptiStruct and Altair ESAComp interfaced with a third-party filament winding simulation package to handle the simulation process.

ThyssenKrupp Elevator

ThyssenKrupp Elevator wanted to explore ways to ensure that an innovative, ropeless elevator system design was as lightweight as possible in order to maximize the loading capacity of the cabins. Altair ProductDesign was selected to explore methods and materials that could help to minimize the weight of the design due to the company’s experience in removing mass from products in the automotive and aerospace sectors.

Reduction of Moving Masses – Streamlined Design for Improved Engine Performance

To expand the rpm range of a motorcycle engine, a new type of rocker arm with lower inertia was needed at KTM. The new rocker arm was required to have the same, or better stiffness and deformation level as the previous design. KTM used Altair HyperWorks™ for nonlinear topology optimization and nonlinear structural analysis to develop the new rocker arm. Thanks to this, the component inertia could be reduced by 15 percent, component mass was reduced by 21 percent, and the stiffness increased by 14 percent which lead to an extension of the rotational speed by 150-200 rpm.